Resistance Welding

Our Resistance Welding sector is the UK market leader in the manufacture of spot welding consumables and equipment. Our products are produced in our own factory in the UK where we employ around 50 skilled engineers to produce resistance welding products to the highest standard. No cheap copper grades, no long lead times waiting for imports, just good customer service, great technical support and the product quality you require.

Our core products include:

- Aluminium Gun Arms

- Copper Gun Arms

- Bent adaptors

- Tip adaptors

- Shunts

- Straight adaptors / Shanks

- Threaded adaptors

- Guide pins

- Weld caps

- Welding cables

- Tip Dressing blades and holders

- SVS Tip dressing equipment and spares – UK distributor

- Various ancillary products

We traditionally supply major automotive manufacturers including Honda, Jaguar, Land Rover, Nissan, BMW, Ford and Vauxhall along with their 2nd and 3rd tier supply chains.

With over 100 man-years of resistance welding experience in our technical support team alone, we are able to provide solutions from the traditional to the advanced, for even the most complex application.

Our Capabilities

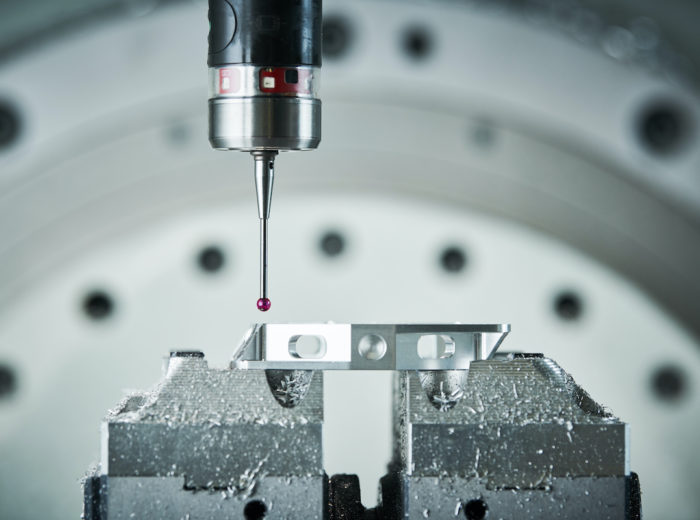

Unique parts for the most demanding situations, from prototypes to full production runs. Our highly experienced designers will support your machining project from start to finish.

Machines

Industry wide we are recognised for our precision CNC machining, advanced infrastructure and engineering excellence

Find out moreMaterials

From Tungsten Carbide to Inconel to Aluminium and everything in between, we work with a wide range of metals

Find out more