Tool Steel

Tool Steel

Hardness: Our tool steel can be hardened, tempered or coated to suite any manufacturing requirement.

Characteristics: We use superior quality tool steels that have excellent wear and abrasive resistance properties. Tool steels are made to a number of grades for different applications.

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools. Their suitability comes from their distinctive hardness, resistance to abrasion, their ability to hold a cutting edge, and/or their resistance to deformation at elevated temperatures (red-hardness). Tool steel is generally used in a heat-treated state.

Uses: Choice of grade varies with application, whether a keen cutting edge is necessary, as in stamping dies, or whether the tool has to withstand impact loading and service conditions encountered with such hand tools as quarrying implements. The higher carbon grades are typically used for such applications as stamping dies, metal cutting tools, etc.

Hardmetal engineering mainly use tool steel for special applications like injection moulding because the resistance to abrasion is an important criterion for a mould that will be used to produce hundreds of thousands of parts.

For more information, please contact us today.

Our Capabilities

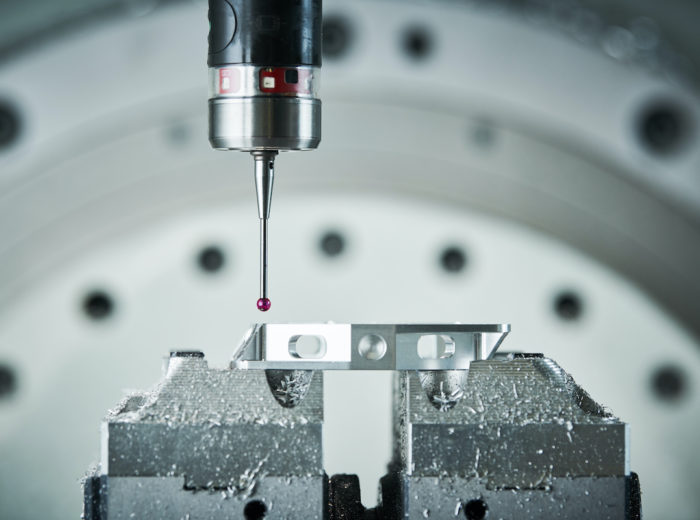

Unique parts for the most demanding situations, from prototypes to full production runs. Our highly experienced designers will support your machining project from start to finish.

Machines

Industry wide we are recognised for our precision CNC machining, advanced infrastructure and engineering excellence

Find out moreMaterials

From Tungsten Carbide to Inconel to Aluminium and everything in between, we work with a wide range of metals

Find out more