Monel

Monel

The Monel group of alloys were created at the start of the century by an employee of INCO, they combined Copper, Nickel and Iron to form the alloy, which was named after the company president, Ambrose Monel. This initial grade is still used today, in various anti-corrosion applications, called Monel 400.

Monel characteristics

- High corrosion resistance. Monel has a high corrosion resistance to acids and alkalis, and impervious to rust. Some alloy variants can endure a fire in pure oxygen.

- Malleable

- Low coefficient of thermal expansion

- Can be welded, brazed and soldered

- Stronger than steel

Market applications

Monel is used for a variety of industries including oil and gas, and marine engineering. The characteristics of Monel are suited to making valves, shafts, pumps, fasteners, heat exchangers and fittings

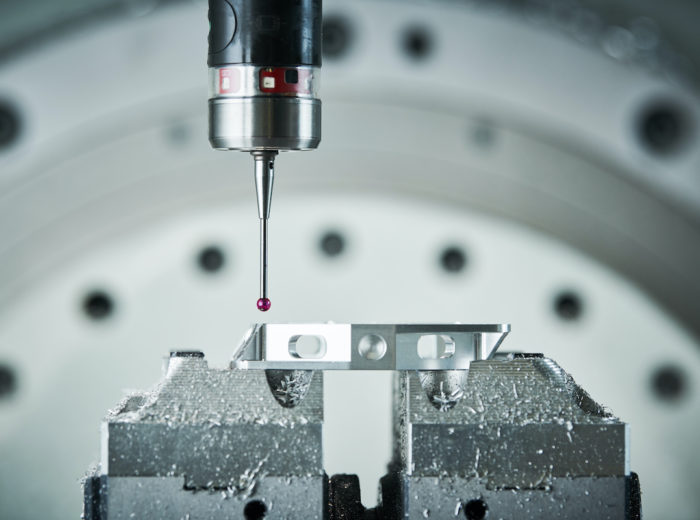

Monel Machining

Monel Aerospace Applications

In the 60s, Monel was widely used in experimental rocket propelled aircraft, Monel was chosen because it maintains its strength at very high temperatures, like the one’s experienced in rocket flight. However Monel has a high density and was replaced by lighter substitutes.

Monel is still used in the aircraft industry as a wire, it is used to ensure fastening remain closed.

Monel Marine Applications

Monel’s corrosion resistance lends itself to marine engineering usages such as strainer baskets, pump shafts, trolling wire, seawater valves, and piping systems. Some alloys are completely non-magnetic and are used for housings for magnetic-field measurement equipment and anchor cables for minesweeping vessels.

Monel Directional Drilling

Monel drill collars are ideal for use in surveying oil wells. Monel collars are used in drilling directional wells which require the well to be steered. Their use allows for faster and more accurate surveys, reduces hazards, and decreases the cost of drilling directional controlled oil wells. The cost reduction comes from the ability of real time surveys from a ‘measure while drilling’ (MWD) tool which has magnetometers inside. The magnetometers need to surrounded by non-magnetic material , such as Monel or Inconel, otherwise they will be unable to read the earth’s magnetic field.

More recently Monel has been substituted with non-magnetic stainless steels.

Monel Chemical Industry Applications

Monels high corrosion resistance to acids and oxygen makes it a useful material for the chemical industry.

Monel is used in the enrichment of Uranium process; large piping sections are used to transport corrosive fluorides

Regulators for reactive cylinder gases for example hydrogen chloride form, where PTFE is not a suitable choice when high delivery pressures are required.

These will sometimes include a Monel manifold and taps prior to the regulator that allow the regulator to be flushed with a dry, inert gas after use to further protect the equipment.

For more information, please contact us today.

Our Capabilities

Unique parts for the most demanding situations, from prototypes to full production runs. Our highly experienced designers will support your machining project from start to finish.

Machines

Industry wide we are recognised for our precision CNC machining, advanced infrastructure and engineering excellence

Find out moreMaterials

From Tungsten Carbide to Inconel to Aluminium and everything in between, we work with a wide range of metals

Find out more